November 2017, I attended a TSP workshop that had an additional workshop on making custom knives.

Patrick Roehrman of MTKnives (owner & master craftsman) mentored 8 attendees.

I’m not a huge fan of neckknives, but I’m a fan of learning from a master craftsman. The workshop was an additional $400. The workshop provided time, talent & materials so when we finished we have a high-end custom knife that sells for $500(if you can even get one, there is a very long wait to buy a knife built by Patrick), plus we get the know-how of someone that has made thousands of knives and spent thousands of dollars/hours learning their craft. The what-not-to-do, is priceless.

Many times Patrick would come to the rescue and “fix” our newbie “signatures” (our mess-ups).

There were many times when it was comforted having the master looking over and helping out when irreversible damage is about to happen. Learning from mistakes is good, but learning from a completely wrecked knife-build is expensive….and frustrating.

The most expensive training is the training you don’t have…and you fail.

To me if you/we have to use a blade for self-defense, that is a very very bad day. Much better to use a handgun for an unexpected attack. Knives are a support-tool for the mission. A neck-knife IMO is for EDC cutting and repair and possible improvised tool for other tasks. My EDC includes a Husky razor blade, SpyderCo endura wave, protac light & sog multi-tool (which also has a blade..that I never use). I abuse the husky razor blade on amazon boxes and almost all my cutting. If I need a longer blade (ex cutting food), I use the spyderco….and now I have the option to use THE KNIFE I MADE!

Using commercial knives is fine, but at a certain point in life, its worth it to have a blade made by a craftsman…not a robot. Patrick’s knife is much much sharper than a brand new razor blade! The people I’ve shown the knife Patrick helped me build, say they have never seen a knife that sharp! Yep, Beyond Razor Sharp!

As you can see from the photos, we had a lot of success and I’m very pleased with the outcome.

PLEASE support Patrick, we want him making knives for life! He is a good/solid guy and has a large family. I think I’ve purchased everything he has for sale online. DOLLAR VOTES FOR GOOD PEOPLE!

I suggest you buy his starter knife(The Genesis II), I know you’ll love it! I hope someday you can upgrade to the knife I built.

BUILD PHOTOS

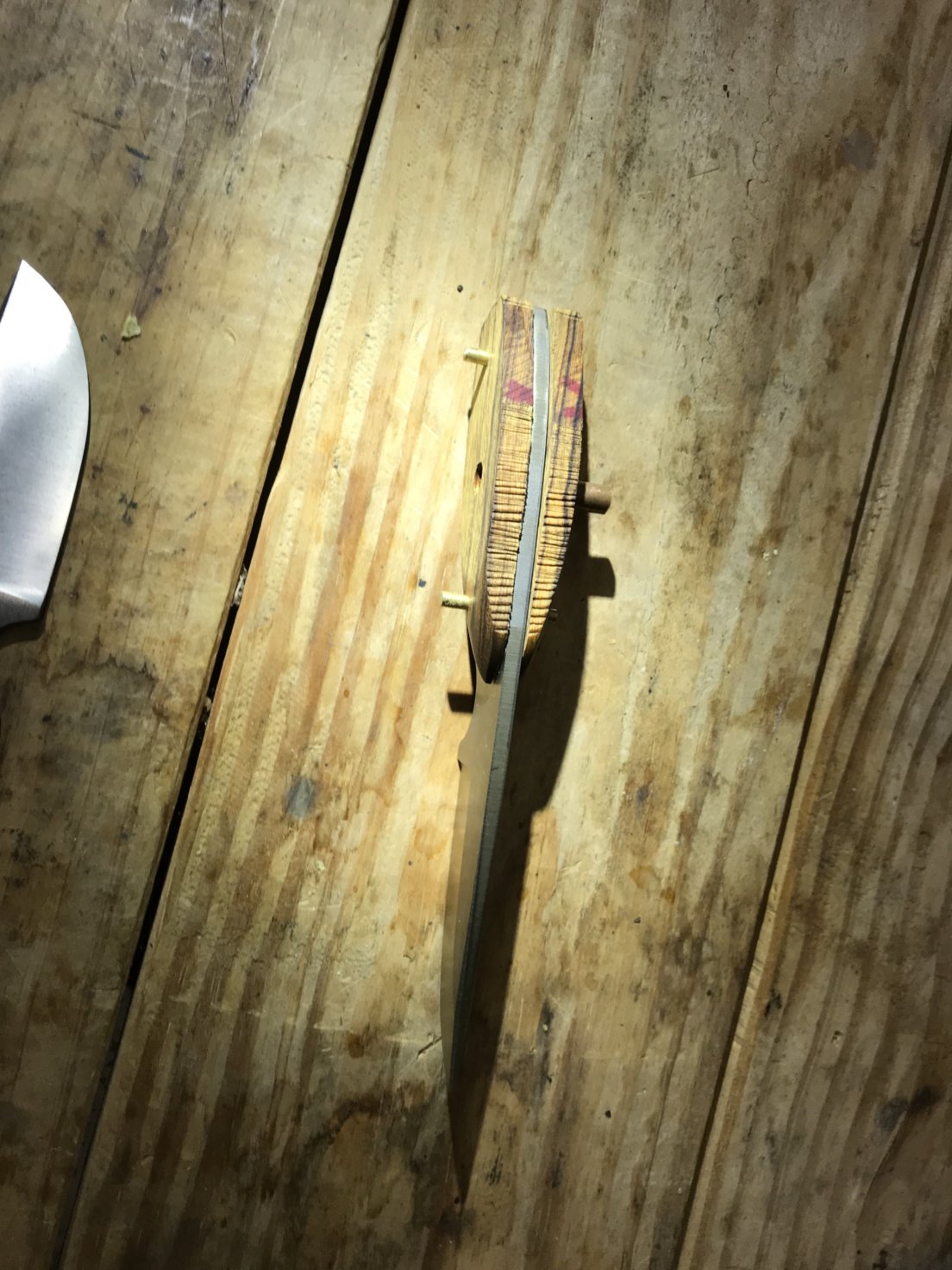

Trying to determine where you want the grains to show-up on the handle takes the experts eye. Doing woodwork, the eye really loves to see the curves of the grains, so set-up is critical IMO.

Here is the photo after a bandsaw, we cut to the OUTSIDE of the marking. So we can grind/sand down to be flush with the steel.

First night, we worked hard to get it ready for the epoxy. Using a q-tip to clean along the edge. We also sanded to perfection the part we wouldn’t be able to sand w/o marring the blade (think front of handle area).

Thomas,

Great review on the knife and the handle construction and finishing. I agree that in this day and age, the knife takes the position of utility and back up, rather than primary weapon. Knowing the strengths and limitations of your tools make your life easier and you safer.

Cheers.